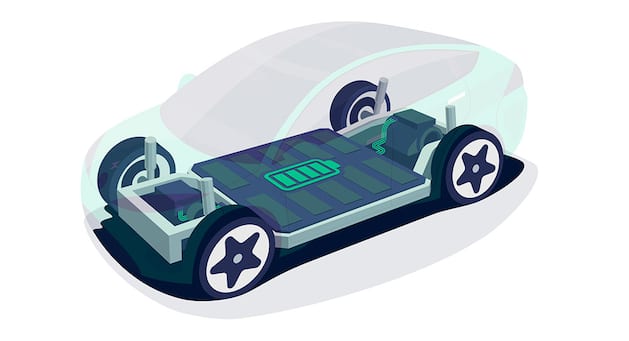

The range of electric cars can be extended by having more space for larger batteries. A model project now shows that the rear axle plays an important role in this.

Electromobility is considered an important building block for future traffic concepts. But so far there has been a problem with the acceptance of electric cars. In addition to the lack of charging stations and long charging times, this is mainly due to the short range of the smaller, cheaper electric car models. Although researchers are already working on more compact batteries or technologies for charging while driving, these technologies are still experimental and complex.

But there is an easier way, as researchers led by Xiangfan Fang from the University of Siegen are now demonstrating. Together with Ford, VW and other project partners, they looked for ways to create more space for the vehicle battery through simple conversions. Because the lack of space for the battery pack is one of the limiting factors for performance and range, especially in small cars with electric drives. The focus of the team was the rear axle, which limits the space available for the battery units to the rear.

“Our idea was actually very simple: we turned the rear axle around and thus moved the cross member of the axle to the rear, in the direction of the trunk,” explains Fang. “This increases the area available under the car for the battery at the front.” The new design of the rear axle creates more space for the battery in the body, which means that the range of the car can be increased by 35 percent – that’s the same around 115 kilometers.

In order to maintain the driving characteristics of the car, however, the Siegen vehicle manufacturer had to make further adjustments to the rear axle: “We first designed the new axle on the computer and integrated it virtually into the body in order to be able to calculate and simulate the properties precisely,” explains Project employee Jens Olschewski. Based on this data, the prototype of the steel axle was then created.

The new rear axle, specially designed for small electric cars, contains several joints which, among other things, ensure that the car behaves normally when braking and does not rear up. In the next step, the axle prototype was built into a Ford Fiesta as a test car. To simulate the weight of the battery, heavy metal plates were placed under the floor of the petrol engine.

The car was then equipped with extensive measurement technology and extensively tested by experts in the test bench and on a test track in Belgium. The result: the comfort and safety of the vehicle are largely retained despite the converted rear axle. In terms of driving dynamics, the test car performed slightly worse in some points than cars with a conventional rear axle. “But the difference is so small that we can certainly compensate for it by further adjustments,” says Fang.

The researchers are currently working on further improving the new axis concept. At the same time, talks are being held with several car manufacturers with the aim of installing the rear axle as standard in small electric cars. “We would be very proud if, in a few years, e-cars drove around with our axle,” says Fang.

Source: University of Siegen

This article was written by Nadja Podbregar

The original of this article “115 kilometers more range! Relocated rear axle upgrades e-cars” comes from scinexx.

On our e-mobility portal EFAHRER.com you will find all e-vehicles available on the German market

You can also arrange a test drive for the car of your choice free of charge and thus start e-mobility in an uncomplicated manner.